Tag: Jerry Leigh

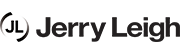

How 3D Design Is Changing Clothing Production

Traditional clothing design is fairly well understood. Everyone has seen a show or movie where a designer sketches out a garment. This is the most traditional way of visualizing a piece of clothing before it’s made. Pattern-making, too, has long been paper-based. Cloth has traditionally been cut by hand. Typically, large fashion houses worked with muslins first in mocking up a garment. This meant that the first patterns could be tweaked with cheap material before using expensive, high-fashion fabrics.

Today, technology is changing every industry. Even artisanal trades like fashion and some kinds of construction have been affected. The biggest changes that are coming to the fashion world are courtesy of 3D tools. Computer-assisted design, or CAD, has long been a go-to in the worlds of architecture and interior design. 3D design has great applications for the fashion world. A lot of these will help the industry save costs and be more environmentally friendly going forward.

Many samples that are produced by hand never actually go into mass production. By making samples with software instead of needles and thread, fashion companies can get an idea of what works and what doesn’t before going into production. As it stands today, samples that aren’t produced are destroyed as waste materials. They are never given away or re-used. That means that some companies can destroy thousands of samples per year. Often, they’re made from materials that don’t readily decompose, like polyesters. 3D design keeps these items from landfills. It also helps companies save money on materials and labor.

3D design also simplifies the whole production process in an increasingly small world. Fashion houses in one country need to send specifications to factories in another. 3D design simplifies this process. The only thing that needs to move is one file, and these can be sent with technology like DropBox. In contrast to sending samples and patterns by mail, this saves a great deal of time. The computer files of 3D designs allow everyone involved in the design process to have the image right in front of them. Everyone, then, is on the same page. This type of thinking is going mainstream, with globally recognized brands like Marks & Spencer adding 3D design to their arsenal of tools.

3 Tips To Improve Your Manufacturing Process

As a business person, you’re keenly aware of how every step of the process impacts your business’ long term health. If there are any areas where you can maximize profits, you want to be capitalizing on that. One area that can often be analyzed in an effort to increase productivity and efficiency in manufacturing. Here’s a quick look at ways you can improve your existing manufacturing process in order to improve your business.

Cut Out The Clutter

It may sound overly simplistic, but taking a look at your manufacturing area is a great first step in improving efficiency. If the area is overrun with clutter, it will quickly lead to chaos. There is a direct correlation between mental stress and clutter among employees, and 75% of doctor visits are stress-related. Ensuring that your production area is neat an organized will empower your employees to maximize their time instead of stumbling around obstacles all over their work area, cut down on their stress which will lead to less work time missed. It’s also worth realizing that a cluttered environment is an unsafe environment; there is no need to put people in harm’s way when issues can be resolved with some good housekeeping.

Making A Profit from Your Loss

Any company’s profit and loss report (often called a P&L Statement) has a line on the sheet to reveal “waste.” That is the cost of the material that is leftover at the end of a production cycle or the cost of the items that were manufactured incorrectly. If you’re willing to think outside the box you can often find other companies that are willing to pay a small amount for what you have leftover. They can then use those items in their own production. You may not get the full price out of them, but any liquidation is better than having a total loss.

Cutting Utility Costs

You probably don’t leave every light in your house on and every faucet pouring water full blast around the clock. In the same vein, look for energy-efficient alternatives in your manufacturing process, and don’t forget to turn off pieces of equipment that aren’t in use. Every dollar counts!

Increasing efficiency in manufacturing is a crucial step in stabilizing the long term health of your company.

Rented Clothing? Here’s What You Need To Know

With more fashion brands focusing on sustainability, it was only a matter of time before renting clothes became the “in thing” to do. To date, there are already a few fashion houses that allow consumers to rent their favorite pieces, return them and then rent something else.

But with so many people wondering whether this really helps decrease their carbon footprint and help aid in the exploitation of factory workers, understanding the process means weighing the pros and cons of rental clothing.

From Couture To Fast Fashion

By far, Rent the Runway is one of the top fashion rental lines that allows consumers to wear designer duds at a fraction of the cost. There are also others that offer the same business model but on a smaller scale. Gwynnie Bee, Le Tote, and other brands also offer subscription-based rentals, which allows customers to rent a specific number of outfits each month.

The idea is to create an environment where fashion is affordable for everyone. The issue is, even with the lower price point, not everyone can afford it. However, with so much positive focus on the decreasing waste that often accompanies clothing manufacturing, rental clothing seems to be on the upswing.

In terms of scalability, the rental clothing business model seems sound. It allows brands to profit from traditional sales but also cater in a new genre of consumers who don’t want to commit or leave a negative mark on the environment. Especially when it comes to water usage and the direct correlation between fashion and a younger demographic, rental clothing lines seem to be the most popular choice.

Final Thoughts

While rented fashion may not be for everyone, it’s not surprising that so many brands are jumping on the rental bandwagon. And not everyone brand will make it when it comes to renting couture, it can reduce their carbon footprint.

For consumers, renting clothing does allow them to save money, change their style and do their part when it comes to decreasing what ends up in a landfill. But with so many still unanswered questions about clothing rental, the only way to know if it will become mainstream or simply be thought of as a passing fad is time.

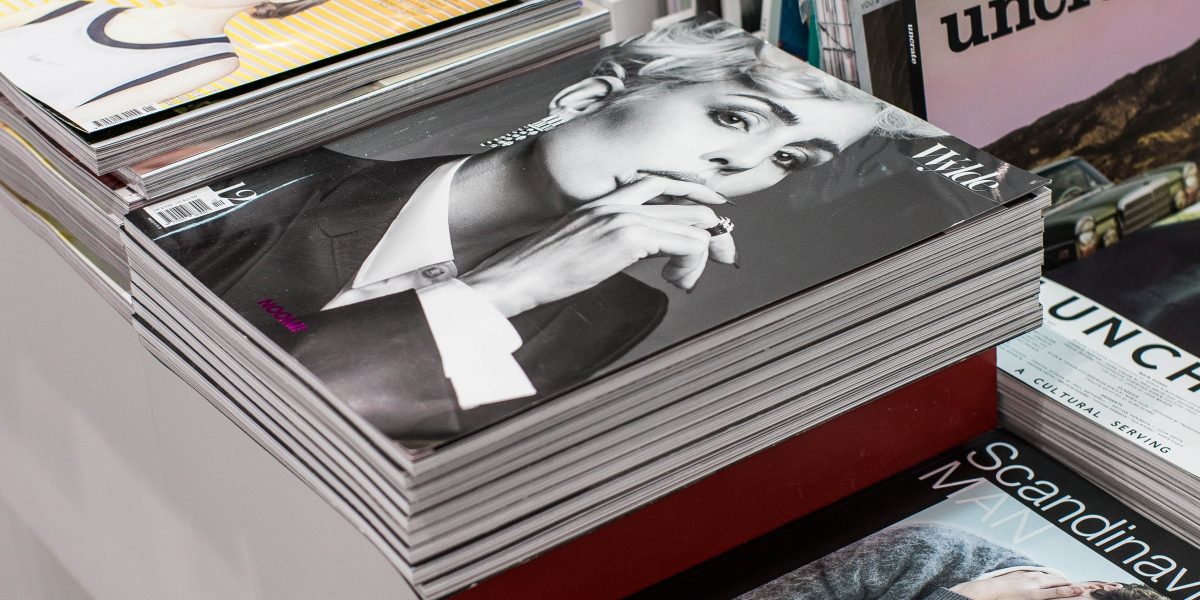

Breaking Down Sustainable Fashion

Sustainability has become a media buzzword over the past few years, and with good reason. People are realizing that it’s important to manage the world’s resources more effectively. High fashion is not often associated with prudence or sustainability. Instead, designers have long cultivated a decadent image. In the 1980s and 1990s, designers like Isaac Mizrahi famously pushed the envelope and lined garments with expensive products like mink fur. Today, fashion is taking a different tack and embracing sustainability.

Issues like climate change have forced fashionistas to confront their spending habits. The trend in fast fashion has meant the production of lots of goods that are worn for only a season or so before being discarded. While the constant production is good for business, the emissions from the mills that make the fabrics and factories where the clothes are pieced together are bad news for the environment. A good way to combat this is to buy investment pieces that will last for several seasons. Replacing buttons or adding trim at home can be a great way to update clothes instead of discarding them. Thrift-store finds can also be upcycled.

Another issue when it comes to sustainability is the use of natural resources in clothing and fabric production. Cotton requires lots of water to be grown, often in parts of the developing world where that resource is precious. These products then often have to be shipped long distances to countries like the US and UK where the end-user purchases them. Making an effort to source locally-produced fabrics and clothing can make a dent in this problem. Purchasing jeans made from recycled denim is also a step in the right direction.

Finally, the issue of human rights in the production of clothing is a serious one. Because the US addressed this issue in the early 1900s, it can be easy to forget that not everyone in the developing world has the same protections. Workers in mills and factories overseas often endure unsafe conditions and discrimination on the job. Women, in particular, are impacted by this. Luckily, the fashion community has become more introspective and interested in these issues. By partnering with organizations like the New Standard Institute, fashion writers, magazines and designers are taking a stand for sustainability.

Looking Into The Future Of Apparel Manufacturing

The apparel industry has been relatively slow to adopt modern data science but that is starting to change. That shift is likely to shape the future of the industry in the coming years and lead to significant benefits for the firms that make good use of new technology. The changes are likely to be significant which means that everyone with an interest in the industry should strive to understand them.

A Focus on the Factory

There has been very little communication between management and the factory floor in the past. Retailers in particular rarely focused on how their products were made. That is starting to change. Technological improvements are making it easier than ever to get detailed information about the manufacturing process and industry leaders are starting to recognize how valuable that information can be in the right hands.

Using Data

Managers need to use that data to identify problems and set clear goals for the factory. That requires a level of engagement on the part of fashion brands and retail businesses that have been absent in the past. Some of the most successful businesses in the field already have a history of doing so but the majority have taken a hands-off approach to their work. The results come from treating the relationship between the brand and the factory as a partnership with strategic implications. The union between the two groups makes it easy to clarify expectations and set goals.

Partnering With the Artisans

Those improvements enable a strategic change in the apparel industry. In the past, the workers and artisans who made apparel had very little feedback on their work processes. They did not know how productive they had been and they had no idea which parts of their workflow needed improvement. Managers who look at the data for their factories can change that. They can get in touch with the workers and give them the information that they need to improve. That can lead to massive boosts to their efficiency, especially when those artisans are deeply engaged in their work. It is likely that more and more people in management will adopt these processes and focus on the factory once they see those benefits.

The Importance of Washing Before You Wear

Many people choose to wear their clothes while they are fresh off the rack. However, this is a big mistake that should be avoided at all costs. It is very important that consumers wash their clothes after purchasing them. There are a variety of reasons that customers should wash their clothing before they are planning on wearing the new items, these are among a few of the reasons.

Allergens

Allergens can cause the skin to break into a rash due to the natural response of a body’s immune system. As a result of contact dermatitis, the name of the condition, customers may experience a delayed rash that will last for weeks until it disappears. The allergens in clothing, among many other possible factors, usually comes from the dyes that manufacturers use in their clothing. Dyes are dispersed when they are freshly applied to clothing items. These dyes normally subside once a clothing item has been washed.

Sickness

Clothes that are in stores may have been tried on a countless number of times before the right customer came along and purchased the items. As can be imagined, stores don’t wash clothes after each customer tries on their clothing items. Therefore, new clothing tends to carry bacteria from a variety of customers. While it doesn’t happen very often, bacteria that is transferred between people can cause someone to become very sick. Detergent does more than removing stains and make clothing smell good, it kills bacteria as well because it is a cleaning agent. On the contrary, using too much detergent can produce an adverse effect by trapping bacteria on the clothing within the excess detergent.

These are only two of the many reasons that customers should wash their clothing before wearing the items. Clothing items look great when they are fresh off of the rack, but washing the items will give a more accurate picture of how the clothing will fit over a long-term time span.

The best way for consumers to kill bacteria on their clothing is by using heat during the drying process. By either placing their clothing in the dryer on a high heat setting or by hanging their laundry out to dry in the sun, customers will create an environment where bacteria can’t survive.

Tools To Improve The Way Your Garments Fit

Customers value the way their clothing fits. The fit of a clothing garment is one of the most important things that customers look for when shopping for clothing or when cleaning out their wardrobes. Customers remain loyal to brands when they are satisfied with the fits that the brands offer them and recognize the consistency of the brands’ products.

Due to many different types of body shapes and sizes, it can be tough for manufacturers to design clothing that fits well with a wide range of people. To cut back on production costs, many manufacturers choose to design clothing garments that fit better for certain body types than others. There are many tools that manufacturers can utilize when aiming to improve the fit of their clothing garments.

Understanding The Audience

A clothing brand needs to understand who their customers are. Additionally, the brand needs to understand the use of clothing. Clothing that is designed for use on a worksite, or protective in nature, needs to fit tighter than clothing designed for a gala. While many clothing manufacturers track the sizes of the clothing that is purchased the most by their customers, they tend to miss the morphotypes of their customers. A morphotype, or body shape, determine the way that a clothing garment looks on a person.

Body Scanning

Many clothing brands obtain measurements by measuring the body dimensions of their ideal customers, not their realistic customers. With the advancements in modern technology, it is possible for brands to obtain more inclusive measurements. Both 3D and 4D scanning allow manufacturers to capture detailed measurements across a wide range of people. Unlike in previous decades, the scans can be saved and adjusted further while the models are unavailable. 3D scanning is able to capture the overall body dimensions of a subject but 4D scanning can capture movements and gestures.

Conclusion

The fit of a clothing garment is a deciding factor when customers are choosing clothing items. Modern technology and the availability of varying software platforms allows manufacturers to design clothing that fit better for a wider range of customers. Satisfaction with the way that a clothing item fits will prevent future returns and exchanges of a brand’s garments.

4 Tips To Make Your Closet More Sustainable

We all want to find ways to be more environmentally-friendly. We look for ways to use less water or create less waste, but your efforts can go further than that. For example, simply organizing your closet and taking care of your clothes can have a positive impact on the environment. If you want to learn how your closet can be more sustainable, consider these helpful tips.

Wash Your Clothes Less Often, and Dry Them Naturally

Washing your clothes accounts for as much as 80 percent of their environmental impact, which makes sense when you consider how much water your washing machine uses. If you only wear a garment once for a short period of time, it probably doesn’t need to be washed immediately. When you do wash your clothes, keep the water around 30 degrees and skip the tumble drier if you want to use less energy.

Organize Your Closet

As strange as it sounds, simply organizing your closet can make your wardrobe more sustainable and cost-effective. When you take the time to organize your closet and make sure that all of your best clothes are there for you to see every day, you might realize how much you really have and what you can do with it. You won’t be tempted to go out and buy new clothes, which leads to fewer trips to the store and fewer big purchases.

Buy Clothes with Organic Cotton

Fabrics with microfibers tend to end up polluting the oceans when they get thrown out or even when they go through your washing machine. When you buy new clothes, stick to garments made from organic cotton or cotton that has been certified by the Global Organic Textile Standard, or GOTS. This will take some additional research on your part, but simply owning organic cotton clothes will make your wardrobe more environmentally-friendly.

Never Throw Out Old Clothes

Finally, never throw away your old clothes. It might be tempting to throw away a shirt because it’s missing a button or a dress with a hole in it, but these can be fixed relatively easily. If you can’t do it yourself, find someone who can. If something really is beyond repair, find a different use for it such as a cleaning rag or even fabric for some new clothes. No matter what you do, it will be better for the environment than simply throwing it in the trash.