Tag: Clothing Manufacturing

2020 Manufacturing Trends

2020 is in full swing, and trends in the fashion industry are beginning to emerge. Many manufacturers are anxious about what the rest of the year will bring. However, if manufacturers are aware of the upcoming trends, they can prepare accordingly. The following are some projections the industry is likely to see.

Prioritizing Sustainability

Most people don’t view the fashion industry as sustainable. With threats such as climate change, however, many consumers are looking for more earth-friendly options. They will want to stay away from brands that require excessive energy consumption, pollution, and waste. Fashion leaders need to change their ways to appeal to customers. Taking significant steps to reduce their carbon footprint, however, can turn into a powerful opportunity for advertising.

The younger generation leading the current earth-friendly movement has stated that they’re open to paying more for clothing that is safer for the environment. Many believe that sustainability is simultaneously one of the industry’s biggest challenges and opportunities.

New Materials

Fashion brands are also interested in creating sustainable fabrics that are safer for the environment than today’s harmful materials. Thanks to recently-developed fiber technology and new materials, there are a variety of opportunities. We can expect to see a strong emphasis on material innovation over the course of the year. In fact, sixty-seven percent of industry leaders believe that using sustainable materials is essential for their company’s future. Some companies have already begun creating alternatives to leather with pineapple leaf fibers.

Future Risks

Unfortunately, many fashion executives are feeling pessimistic about the future of the industry. The world is threatened by geopolitical instability and the risk of an upcoming recession. Every world event has a direct impact on the global economy and the entire fashion industry. To combat these risks, fashion leaders have to exercise caution by planning for risks ranging from trade tensions to new policies.

Fashion manufacturers need to stay on top of things by closely monitoring global events. They should also exercise operational flexibility and digitize all the equipment possible.

The upcoming year presents a variety of challenges to the fashion industry. Manufacturers, however, can stay ahead of the curve by keeping a careful eye on current events and becoming more sustainable than ever before.

An Update on Clothing Production In The US

Trends for clothing production are starting to shift from previously favored foreign manufacturing to garments being marketed and produced in the United States. Clothing production was one of the first industries lost to offshore marketing in the 1960s. Current design, technology, and flexibility changes have allowed for US marketing to be more desirable and make its comeback.

Past Trends

Past trends that changed US clothing production started in the 1960s when outsourcing became cheaper for labor, and there were more efficient processes for products available in foreign countries at that time. The majority of production continued in foreign countries when trade policies of the 1990s wiped out most of the restrictions and duties placed on foreign-made clothes. This made foreign markets even more desirable when it came to profiting from clothing production.

Production Shifts to the US

There are many reasons for clothing production to make its current shift to the United States, including technology advances, consumer attitudes, and merchandising techniques. This change is expected to continue making the United States a bigger part of clothing production from design through marketing.

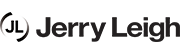

Technology has assisted clothing production in many ways, including production processes and equipment. United States production processes have started using automation technology which includes, computerized production, 3D printing, and robots that can sew called “sewbots.” The United States has made great leaps when it comes to technology and clothing production.

Consumer attitudes and merchandising techniques are a heavy influence on bringing clothing production back to the US. The internet has opened clothing design to be an instant gratification process with companies like Amazon.

Consumers and companies are initiating the production of products in the US through different marketing and campaigning strategies. New processes are helping to make clothing production simpler by requiring less inventory, smaller batches, and quicker turnaround times.

It is exciting that clothing production trends are making a comeback in the United States. This will prove to be a huge asset to our country as clothing production is a large percentage of profit for trade commerce. Clothing production in the US will be favorable for designers located in the states as they will be satisfied in seeing their clothing products-completed from beginning to end within their locale.

How 3D Design Is Changing Clothing Production

Traditional clothing design is fairly well understood. Everyone has seen a show or movie where a designer sketches out a garment. This is the most traditional way of visualizing a piece of clothing before it’s made. Pattern-making, too, has long been paper-based. Cloth has traditionally been cut by hand. Typically, large fashion houses worked with muslins first in mocking up a garment. This meant that the first patterns could be tweaked with cheap material before using expensive, high-fashion fabrics.

Today, technology is changing every industry. Even artisanal trades like fashion and some kinds of construction have been affected. The biggest changes that are coming to the fashion world are courtesy of 3D tools. Computer-assisted design, or CAD, has long been a go-to in the worlds of architecture and interior design. 3D design has great applications for the fashion world. A lot of these will help the industry save costs and be more environmentally friendly going forward.

Many samples that are produced by hand never actually go into mass production. By making samples with software instead of needles and thread, fashion companies can get an idea of what works and what doesn’t before going into production. As it stands today, samples that aren’t produced are destroyed as waste materials. They are never given away or re-used. That means that some companies can destroy thousands of samples per year. Often, they’re made from materials that don’t readily decompose, like polyesters. 3D design keeps these items from landfills. It also helps companies save money on materials and labor.

3D design also simplifies the whole production process in an increasingly small world. Fashion houses in one country need to send specifications to factories in another. 3D design simplifies this process. The only thing that needs to move is one file, and these can be sent with technology like DropBox. In contrast to sending samples and patterns by mail, this saves a great deal of time. The computer files of 3D designs allow everyone involved in the design process to have the image right in front of them. Everyone, then, is on the same page. This type of thinking is going mainstream, with globally recognized brands like Marks & Spencer adding 3D design to their arsenal of tools.

3 Tips To Improve Your Manufacturing Process

As a business person, you’re keenly aware of how every step of the process impacts your business’ long term health. If there are any areas where you can maximize profits, you want to be capitalizing on that. One area that can often be analyzed in an effort to increase productivity and efficiency in manufacturing. Here’s a quick look at ways you can improve your existing manufacturing process in order to improve your business.

Cut Out The Clutter

It may sound overly simplistic, but taking a look at your manufacturing area is a great first step in improving efficiency. If the area is overrun with clutter, it will quickly lead to chaos. There is a direct correlation between mental stress and clutter among employees, and 75% of doctor visits are stress-related. Ensuring that your production area is neat an organized will empower your employees to maximize their time instead of stumbling around obstacles all over their work area, cut down on their stress which will lead to less work time missed. It’s also worth realizing that a cluttered environment is an unsafe environment; there is no need to put people in harm’s way when issues can be resolved with some good housekeeping.

Making A Profit from Your Loss

Any company’s profit and loss report (often called a P&L Statement) has a line on the sheet to reveal “waste.” That is the cost of the material that is leftover at the end of a production cycle or the cost of the items that were manufactured incorrectly. If you’re willing to think outside the box you can often find other companies that are willing to pay a small amount for what you have leftover. They can then use those items in their own production. You may not get the full price out of them, but any liquidation is better than having a total loss.

Cutting Utility Costs

You probably don’t leave every light in your house on and every faucet pouring water full blast around the clock. In the same vein, look for energy-efficient alternatives in your manufacturing process, and don’t forget to turn off pieces of equipment that aren’t in use. Every dollar counts!

Increasing efficiency in manufacturing is a crucial step in stabilizing the long term health of your company.

Breaking Down Sustainable Fashion

Sustainability has become a media buzzword over the past few years, and with good reason. People are realizing that it’s important to manage the world’s resources more effectively. High fashion is not often associated with prudence or sustainability. Instead, designers have long cultivated a decadent image. In the 1980s and 1990s, designers like Isaac Mizrahi famously pushed the envelope and lined garments with expensive products like mink fur. Today, fashion is taking a different tack and embracing sustainability.

Issues like climate change have forced fashionistas to confront their spending habits. The trend in fast fashion has meant the production of lots of goods that are worn for only a season or so before being discarded. While the constant production is good for business, the emissions from the mills that make the fabrics and factories where the clothes are pieced together are bad news for the environment. A good way to combat this is to buy investment pieces that will last for several seasons. Replacing buttons or adding trim at home can be a great way to update clothes instead of discarding them. Thrift-store finds can also be upcycled.

Another issue when it comes to sustainability is the use of natural resources in clothing and fabric production. Cotton requires lots of water to be grown, often in parts of the developing world where that resource is precious. These products then often have to be shipped long distances to countries like the US and UK where the end-user purchases them. Making an effort to source locally-produced fabrics and clothing can make a dent in this problem. Purchasing jeans made from recycled denim is also a step in the right direction.

Finally, the issue of human rights in the production of clothing is a serious one. Because the US addressed this issue in the early 1900s, it can be easy to forget that not everyone in the developing world has the same protections. Workers in mills and factories overseas often endure unsafe conditions and discrimination on the job. Women, in particular, are impacted by this. Luckily, the fashion community has become more introspective and interested in these issues. By partnering with organizations like the New Standard Institute, fashion writers, magazines and designers are taking a stand for sustainability.

The Importance of Washing Before You Wear

Many people choose to wear their clothes while they are fresh off the rack. However, this is a big mistake that should be avoided at all costs. It is very important that consumers wash their clothes after purchasing them. There are a variety of reasons that customers should wash their clothing before they are planning on wearing the new items, these are among a few of the reasons.

Allergens

Allergens can cause the skin to break into a rash due to the natural response of a body’s immune system. As a result of contact dermatitis, the name of the condition, customers may experience a delayed rash that will last for weeks until it disappears. The allergens in clothing, among many other possible factors, usually comes from the dyes that manufacturers use in their clothing. Dyes are dispersed when they are freshly applied to clothing items. These dyes normally subside once a clothing item has been washed.

Sickness

Clothes that are in stores may have been tried on a countless number of times before the right customer came along and purchased the items. As can be imagined, stores don’t wash clothes after each customer tries on their clothing items. Therefore, new clothing tends to carry bacteria from a variety of customers. While it doesn’t happen very often, bacteria that is transferred between people can cause someone to become very sick. Detergent does more than removing stains and make clothing smell good, it kills bacteria as well because it is a cleaning agent. On the contrary, using too much detergent can produce an adverse effect by trapping bacteria on the clothing within the excess detergent.

These are only two of the many reasons that customers should wash their clothing before wearing the items. Clothing items look great when they are fresh off of the rack, but washing the items will give a more accurate picture of how the clothing will fit over a long-term time span.

The best way for consumers to kill bacteria on their clothing is by using heat during the drying process. By either placing their clothing in the dryer on a high heat setting or by hanging their laundry out to dry in the sun, customers will create an environment where bacteria can’t survive.