Tag: California

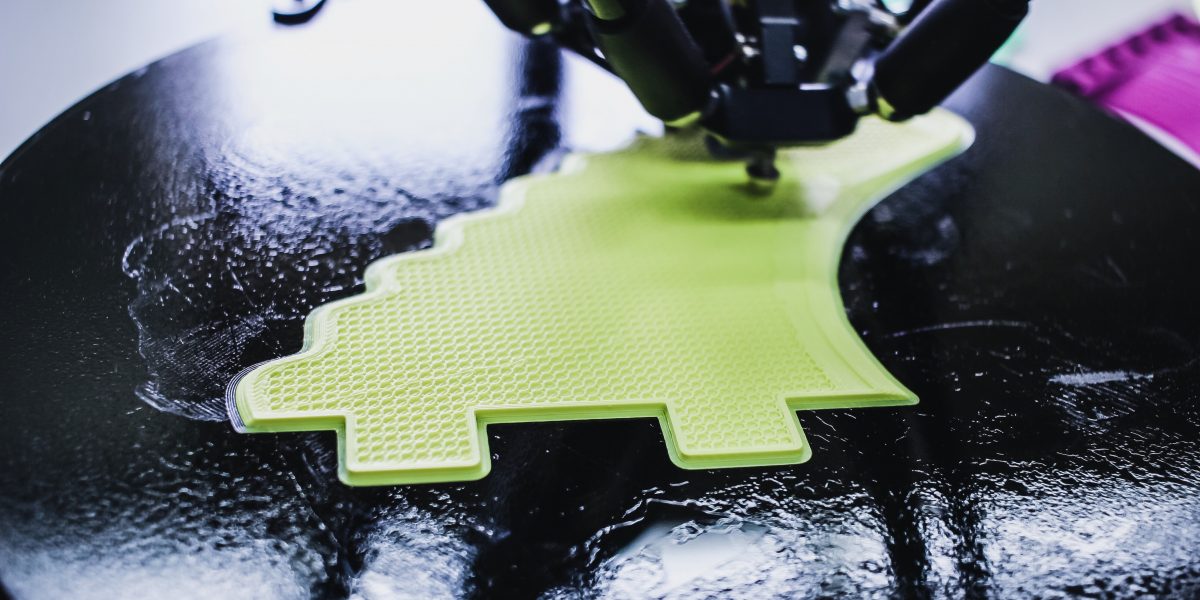

How 3D Design Is Changing Clothing Production

Traditional clothing design is fairly well understood. Everyone has seen a show or movie where a designer sketches out a garment. This is the most traditional way of visualizing a piece of clothing before it’s made. Pattern-making, too, has long been paper-based. Cloth has traditionally been cut by hand. Typically, large fashion houses worked with muslins first in mocking up a garment. This meant that the first patterns could be tweaked with cheap material before using expensive, high-fashion fabrics.

Today, technology is changing every industry. Even artisanal trades like fashion and some kinds of construction have been affected. The biggest changes that are coming to the fashion world are courtesy of 3D tools. Computer-assisted design, or CAD, has long been a go-to in the worlds of architecture and interior design. 3D design has great applications for the fashion world. A lot of these will help the industry save costs and be more environmentally friendly going forward.

Many samples that are produced by hand never actually go into mass production. By making samples with software instead of needles and thread, fashion companies can get an idea of what works and what doesn’t before going into production. As it stands today, samples that aren’t produced are destroyed as waste materials. They are never given away or re-used. That means that some companies can destroy thousands of samples per year. Often, they’re made from materials that don’t readily decompose, like polyesters. 3D design keeps these items from landfills. It also helps companies save money on materials and labor.

3D design also simplifies the whole production process in an increasingly small world. Fashion houses in one country need to send specifications to factories in another. 3D design simplifies this process. The only thing that needs to move is one file, and these can be sent with technology like DropBox. In contrast to sending samples and patterns by mail, this saves a great deal of time. The computer files of 3D designs allow everyone involved in the design process to have the image right in front of them. Everyone, then, is on the same page. This type of thinking is going mainstream, with globally recognized brands like Marks & Spencer adding 3D design to their arsenal of tools.

Looking Into The Future Of Apparel Manufacturing

The apparel industry has been relatively slow to adopt modern data science but that is starting to change. That shift is likely to shape the future of the industry in the coming years and lead to significant benefits for the firms that make good use of new technology. The changes are likely to be significant which means that everyone with an interest in the industry should strive to understand them.

A Focus on the Factory

There has been very little communication between management and the factory floor in the past. Retailers in particular rarely focused on how their products were made. That is starting to change. Technological improvements are making it easier than ever to get detailed information about the manufacturing process and industry leaders are starting to recognize how valuable that information can be in the right hands.

Using Data

Managers need to use that data to identify problems and set clear goals for the factory. That requires a level of engagement on the part of fashion brands and retail businesses that have been absent in the past. Some of the most successful businesses in the field already have a history of doing so but the majority have taken a hands-off approach to their work. The results come from treating the relationship between the brand and the factory as a partnership with strategic implications. The union between the two groups makes it easy to clarify expectations and set goals.

Partnering With the Artisans

Those improvements enable a strategic change in the apparel industry. In the past, the workers and artisans who made apparel had very little feedback on their work processes. They did not know how productive they had been and they had no idea which parts of their workflow needed improvement. Managers who look at the data for their factories can change that. They can get in touch with the workers and give them the information that they need to improve. That can lead to massive boosts to their efficiency, especially when those artisans are deeply engaged in their work. It is likely that more and more people in management will adopt these processes and focus on the factory once they see those benefits.

Tools To Improve The Way Your Garments Fit

Customers value the way their clothing fits. The fit of a clothing garment is one of the most important things that customers look for when shopping for clothing or when cleaning out their wardrobes. Customers remain loyal to brands when they are satisfied with the fits that the brands offer them and recognize the consistency of the brands’ products.

Due to many different types of body shapes and sizes, it can be tough for manufacturers to design clothing that fits well with a wide range of people. To cut back on production costs, many manufacturers choose to design clothing garments that fit better for certain body types than others. There are many tools that manufacturers can utilize when aiming to improve the fit of their clothing garments.

Understanding The Audience

A clothing brand needs to understand who their customers are. Additionally, the brand needs to understand the use of clothing. Clothing that is designed for use on a worksite, or protective in nature, needs to fit tighter than clothing designed for a gala. While many clothing manufacturers track the sizes of the clothing that is purchased the most by their customers, they tend to miss the morphotypes of their customers. A morphotype, or body shape, determine the way that a clothing garment looks on a person.

Body Scanning

Many clothing brands obtain measurements by measuring the body dimensions of their ideal customers, not their realistic customers. With the advancements in modern technology, it is possible for brands to obtain more inclusive measurements. Both 3D and 4D scanning allow manufacturers to capture detailed measurements across a wide range of people. Unlike in previous decades, the scans can be saved and adjusted further while the models are unavailable. 3D scanning is able to capture the overall body dimensions of a subject but 4D scanning can capture movements and gestures.

Conclusion

The fit of a clothing garment is a deciding factor when customers are choosing clothing items. Modern technology and the availability of varying software platforms allows manufacturers to design clothing that fit better for a wider range of customers. Satisfaction with the way that a clothing item fits will prevent future returns and exchanges of a brand’s garments.